Furthermore, spindles may be equipped with distinct tool Keeping systems to support a variety of cutting tools. This flexibility enables operators to accomplish different machining functions without the need to transform spindles frequently.

Open loop stepper systems run in one direction – from the controller towards the stepper motor. Then again, closed loop systems operate two strategies, and can consequently receive suggestions.

3D printing is considered ideal for quite limited operate, intricate pieces with elaborate geometries, with CNC much better for more rapidly, cheaper parts in metal, wood or other challenging resources.

It controls the depth and orientation of your tools, making certain smooth and accurate cuts. This system operates in coordination Along with the servo motor, making it a crucial component in identifying the quality of the completed item.

CNC milling is a very exact and functional approach appropriate for various apps, is able to form metals, plastics and wood, and can be quite brief.

Spindles come in numerous types, for example belt-driven or immediate-driven, Each individual offering unique benefits determined by particular machining necessities. The pace and ability from the spindle Participate in an important purpose in pinpointing the overall efficiency and precision on the machine.

5-axis CNC machines Construct on this, introducing A and B axes to the initial X, Y and Z axes. A and B are axes all over which the Device, such as the CNC milling Instrument, can rotate.

Then together arrived the initial computer systems. These early desktops, nevertheless primitive, could create their own punched tape based upon sure inputs. This dramatically improved the speed at which instructions could possibly be produced.

Machining centers perform on several axes to control the movement on the cutting tool and the workpiece. The coordination of those axes makes certain specific cuts and intricate styles. Listed here’s a breakdown of the main axes and their needs:

For more complicated duties requiring intricate cuts from several angles, the 5-Axis Machining Center shines. This type delivers Improved precision and suppleness by making it possible for rotation alongside five axes concurrently.

The ATC system features a Software magazine in which unique cutting tools are stored, enabling the machine to switch amongst tools seamlessly. This boosts click here production performance and provides versatility in machining functions.

Early issue detection thanks to an built-in early warning system giving Increased quality assurance

The VMC is noted for its flexibility in handling different materials like metals, plastics, and composites with high accuracy and effectiveness. Its design enables operators to operate on various sides of the workpiece without the need to reposition it constantly.

Numerical Management machines are managed by numerical Directions known as packages. They are fed in the machine by means of punch cards, necessitating proficient operators to observe and use. NC machine plans are challenging to modify, for instance if mistakes arise.

Mara Wilson Then & Now!

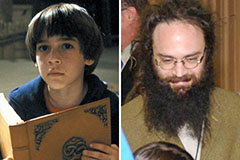

Mara Wilson Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Destiny’s Child Then & Now!

Destiny’s Child Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now!